| |

|

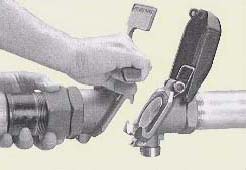

Alloy 20 Couplings in sizes 2” & 3” |

| |

|

|

Alloy

20 (also called Carpenter 20Cb-3®) is an austenitic stainless

steel possessing excellent resistance to hot sulfuric acid

and many other aggressive environments which would readily

attack Type 316 stainless. This alloy exhibits superior

resistance to stress-corrosion cracking in boiling 20 to

40% sulfuric acid.

20Cb-3 stainless is also stabilized to limit inter-granular

attack, even in the sensitized condition. Corrosion tests

on annealed and sensitized material conducted in the Ferric

Sulfate - 50% Sulfuric Acid Test resulted in rates of 0.002

inches per month maximum.

This material has found wide use in all phases of the chemical

and allied industries. It has been used extensively in the

processing of synthetic rubber, high-octane gasoline, solvents,

explosives, plastics, synthetic fibers, heavy chemicals,

organic chemicals, pharmaceuticals, and agrichemicals.

|

|

Some of

the areas of use for Alloy 20 are:

Fans

Mixing tanks

Agitators

Distillation towers

Heat

exchangers

Process piping

Bubble caps

Metal cleaning

& pickling

tanks spray Pickling equipment

Pump shafts and rods valve

stems

Bolts

Nuts

Washers

Tie rods

Continuous-line pickling equipment

Racks

|

| |

| Important Note:

The following 5-level rating scale is intended for comparative purposes only. Corrosion testing is recommended; factors which affect corrosion resistance include temperature, concentration, pH, impurities, aeration, velocity, crevices, deposits, metallurgical condition, stress, surface finish and dissimilar metal contact. |

| Nitric Acid |

Good |

|

Sulfuric Acid |

Excellent |

| Phosphoric Acid |

Good |

|

Acetic Acid |

Good |

| Sodium Hydroxide |

Good |

|

Salt Spray (NaCl) |

Excellent |

| Sea Water |

Moderate |

|

Sour Oil/Gas |

Good |

| Humidity |

Excellent |

|

|

|

|

|

|

| Please see dimensions, weights and complete

technical specifications for Alloy 20 couplings in our

Catalog on

pages 9, 11, 12, and 13. |

|

| |

|

|